For startup founders and small business owners building physical products, hardware development can feel like a constant cash leak.

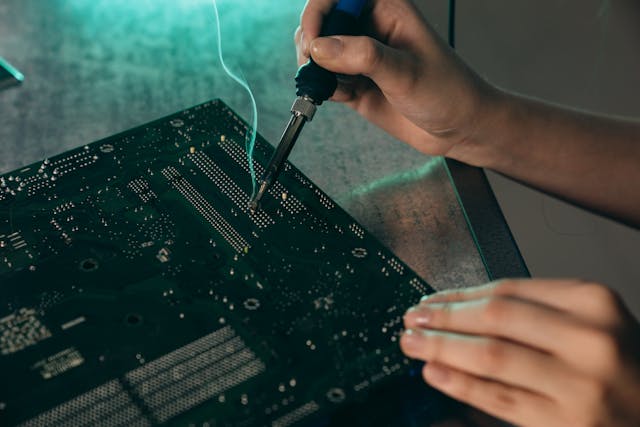

Unlike software, where mistakes can often be fixed with a patch, hardware errors are paid for in real dollars: new boards, new parts, more testing, and more time before you can ship.

One of the most underestimated budget killers in hardware projects is PCB manufacturing. The wrong manufacturing partner can quietly turn a manageable development budget into an expensive lesson.

The right one, on the other hand, can help you avoid costly mistakes, reduce rework, and stretch your limited capital much further than you might expect.

Why Hardware Mistakes Hurt More Than Software Mistakes

If you’re building a hardware startup or side business, cash flow matters. Every delay pushes back revenue. Every redesign eats into the runway.

Common PCB-related issues like incorrect impedance, EMI failures, or poorly executed stackups often don’t show up until boards are assembled and tested.

By then, you’ve already paid for:

- PCB fabrication

- Component sourcing

- Assembly costs

- Engineering time

Fixing those problems usually means starting the cycle again. For a founder managing a tight budget, even one unnecessary board re-spin can represent thousands of dollars lost.

PCB Manufacturing Is a Financial Decision, Not Just a Technical One

Many first-time founders treat PCB manufacturing as a commodity purchase: upload files, compare prices, and pick the cheapest option that meets the basic requirements.

That approach works for simple boards. It often fails for complex hardware projects that involve:

- Multi-layer stackups

- High-speed or RF signals

- Tight impedance requirements

- Compact or dense layouts

Manufacturers that lack strong engineering support may build exactly what you send, even if it’s likely to cause problems. When that happens, the financial risk shifts entirely onto you.

A more capable manufacturer reduces that risk by acting as a second set of eyes before money is spent.

How Engineering Review Saves Real Money

One of the most valuable services a PCB manufacturer can offer isn’t faster turnaround or lower unit cost; it’s early design feedback.

For example, PCBSync reviews stackups and manufacturing details before production begins.

This type of review can uncover issues that might otherwise lead to:

- Boards missing impedance targets

- Signal integrity problems that require redesign

- Manufacturing tolerances that push costs higher

Catching these problems early is significantly cheaper than discovering them after boards are built and assembled. For founders, this can be the difference between staying within budget and needing to raise more money sooner than planned.

The Hidden Cost of “Cheap” PCB Quotes

Low upfront pricing is appealing, especially when cash is tight. But the cheapest quote often ignores downstream costs.

A board that’s inexpensive to fabricate but fails testing can end up costing far more than a slightly higher-priced board that works the first time correctly.

Hidden costs include:

- Additional prototype rounds

- Engineering hours spent debugging instead of building features

- Delayed product launches

- Missed sales opportunities

From a personal finance perspective, this is similar to buying a low-quality tool that breaks and needs replacement. The initial savings disappear quickly.

Fewer Re-Spins Mean Better Cash Flow

Every additional PCB revision impacts cash flow. Even if each spin seems manageable, they compound quickly.

Manufacturers with consistent processes, tight quality control, and experience with complex designs help reduce the number of re-spins required.

Fewer re-spins mean:

- Lower total development spend

- More predictable budgeting

- Faster path to revenue

For bootstrapped founders or small teams, this predictability is critical. Knowing how much you’ll spend and when makes financial planning far easier.

Scaling Without Financial Surprises

Another often-overlooked financial risk is inconsistency between prototype and production builds. A board that works in prototype but behaves differently in production can force last-minute changes that disrupt budgets and timelines.

Manufacturers that maintain consistent materials, processes, and quality standards across volumes help prevent these surprises. This consistency allows founders to scale production with confidence, without setting aside large contingency budgets for unexpected issues.

Treating Manufacturers as Long-Term Partners

From a startup finance standpoint, the best manufacturers aren’t just vendors, they’re partners in cost control.

A responsive manufacturer that communicates clearly, flags risks early, and adapts to project needs can help you make smarter tradeoffs between performance and cost. Over multiple product iterations, this relationship can save significant money and reduce stress.

Final Thoughts

For founders and small business owners building complex hardware, PCB manufacturing is more than a technical step; it’s a financial decision that directly affects cash flow, timelines, and runway. The right PCB manufacturer can help you avoid expensive rework, reduce delays that push back revenue, and make your development costs far more predictable.

While it’s tempting to focus on the lowest upfront quote, long-term savings come from choosing a partner who catches problems early and delivers consistent results. In the end, protecting your budget isn’t about spending less on fabrication; it’s about spending smarter and avoiding mistakes that quietly drain your capital.

Leave a Reply